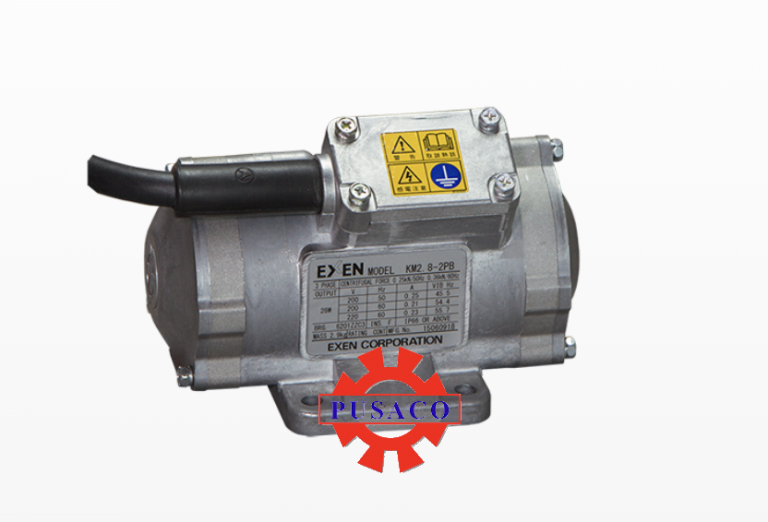

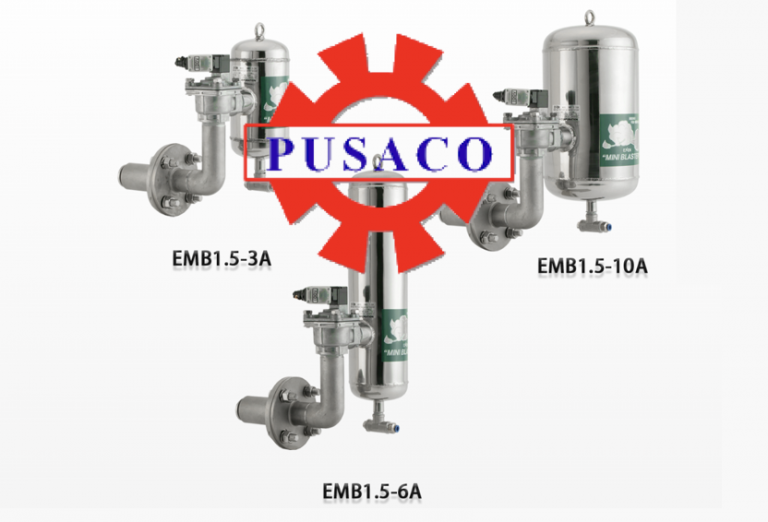

Complete oil-free! Ultracompact turbine vibrator

This product is used for the following applications:

- Powder plant: used for prevention of blockage of powder in small hopper (made of resin)

- Prevention of buildup at the curve in belt conveyor for conveying eye-drops

- Used in various automobile part manufacturing line (improvement of buildup in conveyance, ejection of cutting workpiece in cutting process), part arrangement, removal of burrs from electric components)

Features

Turbine vibrator is a pneumatic vibrator used in complete oil-free. Like the conventional ball vibrator, simply supplying compressed air into the turbine vibrator will easily generate vibration. (Lubrication is strictly prohibited to use for supply air) Because the turbine portion rotating at high speed does not contact with housing portion and generates vibration, the turbine vibrator produces very low level of noise and is friendly to the plant environment. The housing body, turbine, and air joint of turbine vibrator are items conforming to Food Sanitation Act, and other outer parts including muffler and cover bracket use stainless steel material. Therefore, the turbine vibrator can be used safely in food, pharmaceutic chemical and precision part industries. Turbine vibrators are available in a total of three models: model BTP of resin housing and model BTS of stainless steel (SUS304). All of joint, muffler, cover, etc. use stainless steel material. As equipment for preventing clogging or adhesion of powder, turbine vibrator is a flow aid product that is helpful for an area where minor vibration is required or for preventing clogging in hopper or chute. (Cautions for operation) Bearing and lubricant used in vibrator meet the food specification, and their service lives are shorter than bearing for general industry. In the use of turbine vibrator, it is recommended to avoid continuous operation and to perform intermittent operation. Replacement frequency of bearing is 150 hours (in our company’s test) as a rough indication, and if vibration frequency is lowered or an abnormality such as abnormal sound is detected, replace the bearing ahead of time. If the vibrator is used in environment other than fool that is not related to aspect of hygiene, when bearing is replaced for the first time after the new product is installed, replacing it with a general-purpose bearing can extend the service life. For details, contact our sales staff. (However, because the above instruction is for functional maintenance on aspect of hygiene, we do not assemble new products, using such bearing or grease.)