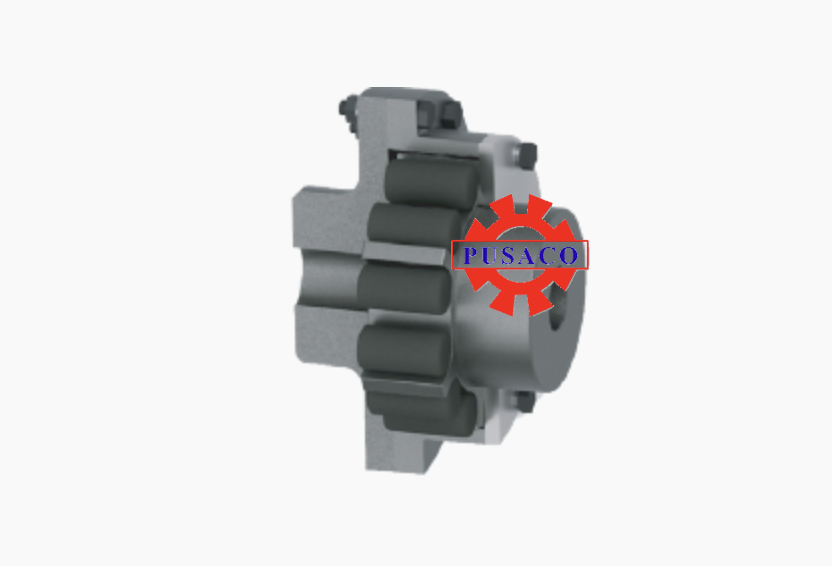

RHS Couplings absorbs the impact load generated in starting and the vibration generated during operation due to eccentricity and declination angle between the axes by creating compression elasticity through the process of outer flange and inner flange and the insertion of round rubber bush between the flanges to protect prime motors and driven motors. Since it uses rubber bush, which is a high elastic body, it shows excellent performance when it is equipped in diesel engine or equipment where impact load is high.

- Excellent absorptive ability against vibration and impact load.

- High torsional torque.

- Zero backlash possible on axis connection.

- Small axial movement and easy axis alignment.

- Combination of large axial diameter available and easy to assemble and disassemble.

- It is possible to reduce the space between the prime motor and driven motor.