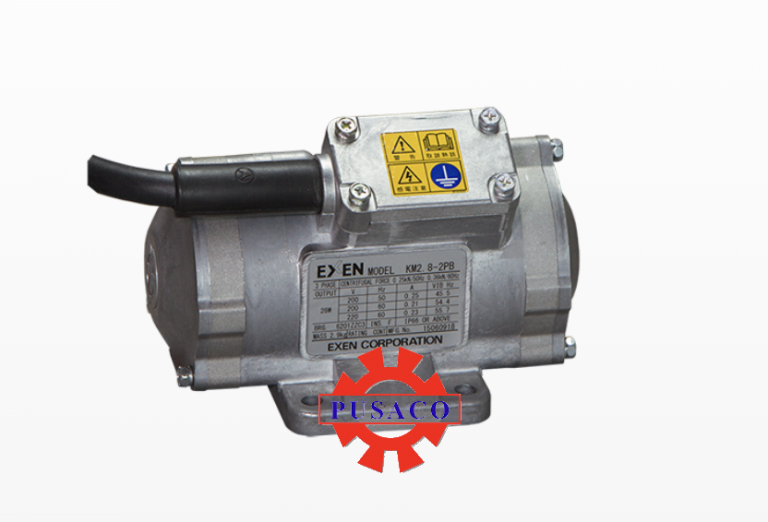

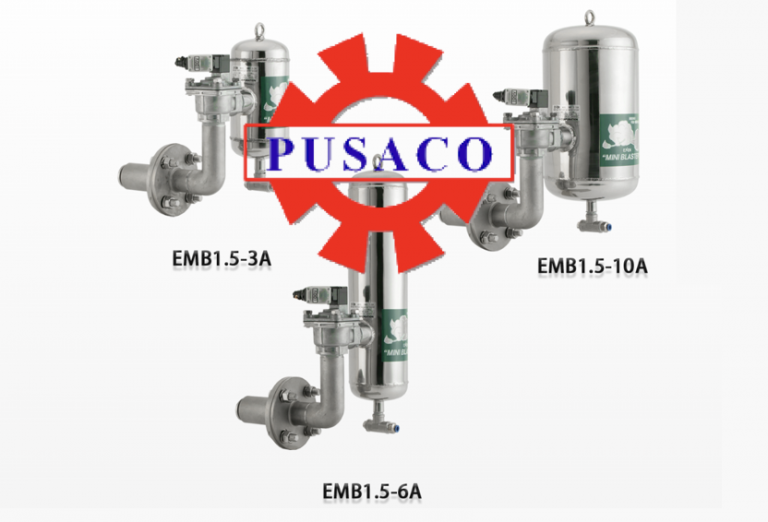

Direct impact type hammering equipment for expanded applications

This product is used for the following applications:

- Food factory: RKD is used to remove the chocolate from the mold in chocolate factory

- Elimination of adhesion on wall surface in rotary drier

- Removal of extra paint in powder paint

- Prevention of adhesion on wall surface of workpiece for furnace, knocking off of weld spatter, prevention of adhesion on workpiece on mesh in drying furnace

- Used for inscription

- Used for telescope enforcement

- Removal of water on base

Features

The Air knocker (Indirect impact type) is a unique equipment in which the force of compressed air causes the piston to energetically strike the base surface, which eliminates the adhesion or clogging of powder. In addition, this knocker is excellent in safety and economics because it can be used only by air supply, and it can be used safely for powder that has a characteristic to show adhesion when receiving the centrifugal vibration.

Operating principle of Air knocker

- The compressed air flowed into the knocker is first supplied to the valve chamber to depress the mushroom valve and then is stored in the accumulator.

- When the three-way valve is actuated to exhaust the air from the valve chamber, the compressed air in the accumulator moves the mushroom valve upward.

- When the mushroom valve moves, the compressed air in the accumulator depresses the piston energetically, which strikes the base surface. That impact force eliminates the adhesion or blockage of powder.